Sequential PSA Nitrogen Generators

Sequential PSA Nitrogen Generators

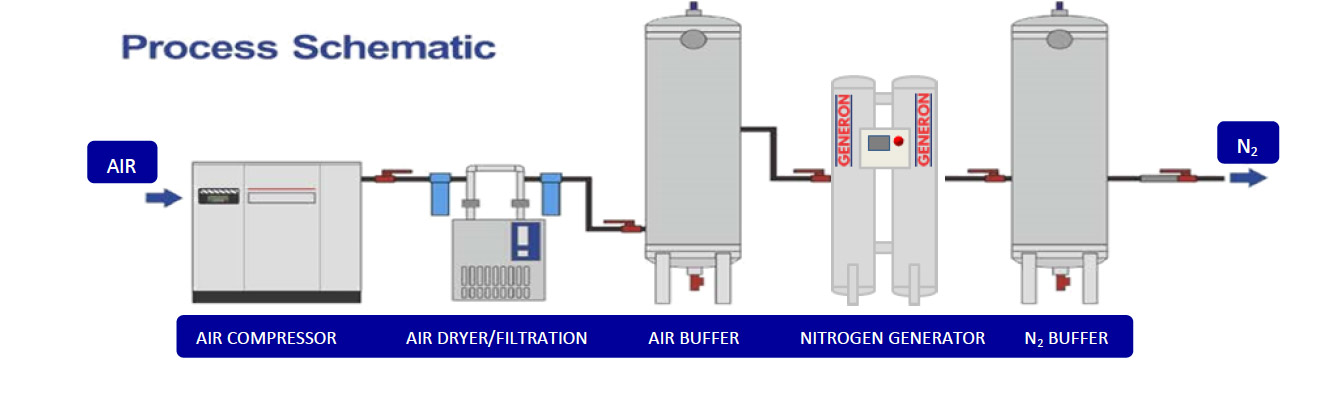

Our Sequential Pressure Swing Adsorption (PSA) Nitrogen Generator, manufactured by GENERON, is comprised of numerous pairs of Twin Tower Adsorber Vessels. The generators operate on alternating cycles and work by separating N2 from compressed air through the use of PSA technology. This line has a reduced footprint is ideal for medium/large flow rates.

Standard Model Features:

- High Cycle Life Pneumatic and Electric Valves

- ASME Adsorber Vessels

- Pressure Safety Valve

- Oxygen Analyzer and Calibration Kit

- PLC Control System

- Nitrogen Pressure Regulator

- Carbon Steel Skid

- Overall Low Height ideal for Compact Areas

- High Performance Adsorbent Media

- Exhaust Silencing Muffler

Options & Upgrades:

- Post Filtration Packages

- Inlet Filtration Packages

- Product Flow Meters

- Auto Shut Down/Startup/Standby mode

- Compressed Air Buffer Tanks

- Off Specification Circuits

- Nitrogen Buffer Tanks

- Master Controllers for multiple unit operations

- HMI Display Screens

- Enhanced PLC w/ Telemetry

- Dew Point Analyzers

- Energy Saving Part-Load Control

Advantages:

- Low Gas Generating Cost

- Automatic Unattended Operation

- Heavy Duty Construction

- Easy Installation

- Low Energy Consumption

- Low dBa Levels

- Low Maintenance

- Highly Reliable

- No Hazardous Storage

| PARAMETERS | Dimensions: | 116″ – 240″ L x 96″ W x 108″ H |

| Weight | 8,000 – 45,000 lbs | |

| Power Requirement: | 900 – 1,500 WATT @ 120 VAC Supply | |

| Inlet Air Connection: | 3″ – 6″ 150# RF | |

| N2 Outlet Connection: | 2″ – 4″ 150# RF |

| Nitrogen Purity / Flow Rate | ||||||||||||

| Model | psig | barg | 97% | 99% | 99.90% | 99.99% | 99.999% | |||||

| Size | scfm | Nm3/h | scfm | Nm3/h | scfm | Nm3/h | scfm | Nm3/h | scfm | Nm3/h | ||

| 2xNS-20-65 | 90 to 145 | 6.2 to 10 | 171-292 | 271-463 | 126-207 | 200-329 | 72-108 | 115-171 | 49-58 | 77-93 | 25-21 | 41-33 |

| 2xNS-24-64 | 90 to 145 | 6.2 to 10 | 246-420 | 390-665 | 181-298 | 288-472 | 104-155 | 165-246 | 70-84 | 111-133 | 37-30 | 59-48 |

| 2xNS-30-56 | 90 to 145 | 6.2 to 10 | 341-582 | 541-922 | 252-413 | 399-654 | 144-215 | 229-341 | 98-117 | 155-185 | 51-42 | 81-66 |

| 2xNS-36-56 | 90 to 145 | 6.2 to 10 | 496-846 | 786-1340 | 366-600 | 579-951 | 210-313 | 333-495 | 142-170 | 225-269 | 75-61 | 118-97 |

| 3xNS-36-56 | 90 to 145 | 6.2 to 10 | 745-1269 | 1179-2010 | 549-901 | 869-1427 | 315-469 | 500-743 | 213-255 | 338-404 | 112-92 | 178-146 |

| 4xNS-36-56 | 90 to 145 | 6.2 to 10 | 993-1692 | 1572-2680 | 732-1201 | 1159-1902 | 421-626 | 666-991 | 284-340 | 450-539 | 150-122 | 237-194 |

| 5xNS-36-56 | 90 to 145 | 6.2 to 10 | 1241-2116 | 1965-3350 | 915-1502 | 1449-2378 | 526-783 | 833-1239 | 356-425 | 563-673 | 187-153 | 297-243 |

| 6xNS-36-56 | 90 to 145 | 6.2 to 10 | 2483-4232 | 3931-6700 | 1831-3004 | 2899-4757 | 1052-1566 | 1666-2479 | 712-851 | 1127-1347 | 375-307 | 594-486 |

| Flow and pressure values are averages throughout a cycle with tolerances of ±4%. Performance data based on 68°F (20°C) PSA inlet temperature. Standard conditions: 68°F (20°C) and 14.696 psi (1 atm). Custom sizes are available upon request. | ||||||||||||