Nitrogen Generator Skids

GENERON Group Membrane separation system is engineered for more effective Nitrogen generation & mixed gas purification. These kinds of Skid-Mounted systems are typically used in Ammonia plants, the Oil and Gas Industry, Chemical Manufacturing Facilities, and Refineries. We engineer both standard designs and custom specifications to give our customers a more reliable and affordable membrane-separation solution.

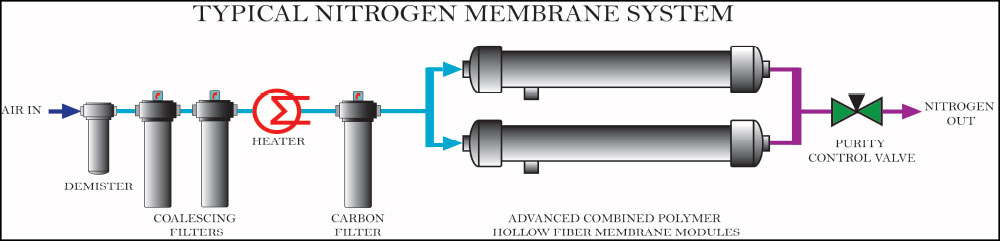

Our manufacturer’s membrane modules contain more than one million fibers. A compressed feed air passes through the fiber bores at one end of the module, enriched nitrogen gas leaves from the opposing end. During this process, O2 and water vapor are emitted from the feed air and move through the membrane module.

Our high-standard UL/CUL, ISO-9001, PED/PE, and ASME certified facilities will surely exceed your expectations.

Applications:

- Auto Clave

- Brazing

- Chemical and Pharmaceutical Blanketing

- Cylinder-Filling

- Gas Assisted Injection Molding (GAIM)

- General Blanketing

- Heat Treating Ferrous/Non-Ferrous Metals

- Inert Flammable Liquids and Gases

- Marine

- Packaging Food

- Refineries

Standard Features:

- Design based on Customer Specifications

- .01 Micron Coalescing Filter w/ drain

- Fail Safe Packaging

- Hollow Fiber Membranes

- Activated Carbon Filter

- Inlet/Outlet Pressure Gauge

- Manual Purity Control Valve

- NEMA 12 Cabinet Enclosure

- Oxygen Analyzer w/ Calibration Valve

- Performance Test, Report, and certificate

- Pressure Safety Valve

- PLC Control System w/ HMI Feature

- Skid w/ Lifting lugs

Optional Features:

- 1 MicronCoalescing Filter

- Automatic Purity Control Valve

- Auto/Standby Mode

- Demister/Moister Separator

- Dew Point Analyzer

- Hazardous Area Classification

- Enhanced PLC w/ Telemetry

- NEMA 4X Control Cabinet Enclosure (316SS)

- Nitrogen Booster Compressor

- Primary Air Compression

- Product Flow Meter

- Process Heater

- Seawater cooled Air Compressor

Nitrogen Package with 100% redundancy