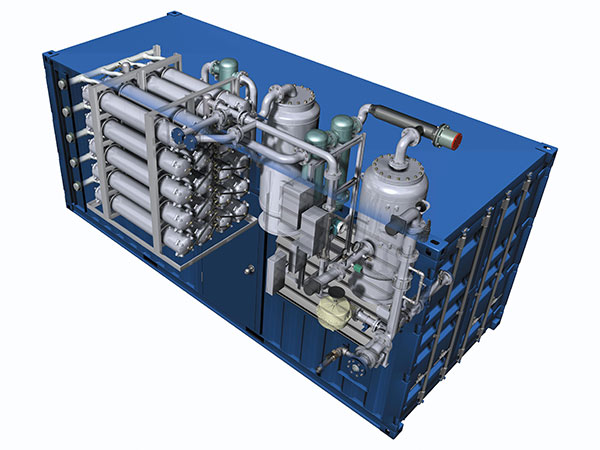

Nitrogen Generator Containerized Mobile Systems

Our Membrane separation systems are designed and engineered for effective mixed gas purification and Nitrogen generation. Skid mounted Nitrogen generator systems are common in Oil and Gas Industries, Refineries, Chemical Manufacturing Facilities, Ammonia Plants, and Pipeline Maintenance. These units are designed to be operated onshore and offshore. Our engineers build both standard and custom designs to provide our customers with a cost effective and reliable membrane-separation solution.

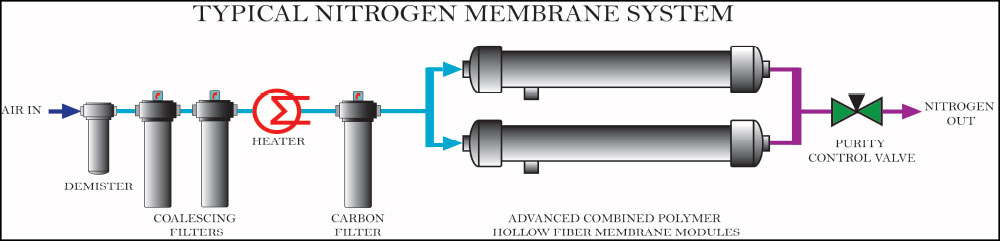

The Membrane Modules we use contain over a million fibers. Our process entails compressed feed-air being passed along the fibers’ bores at the end of the module, and enriched nitrogen product gas exiting the other end of the module. Water vapor and Oxygen are then removed selectively and vented out of the feed air, flowing through the module.

Our ISO-9001, UL/CUL, ASME, PED/PE, certified shops and facilities meet the highest standards are ensure your expectations are exceeded.

Applications

- Auto Clave

- Blanketing of Chemical and Pharmaceuticals

- Brazing

- Cylinder Filling

- Food Packaging

- GAIM (Gas Assisted Injection Molding)

- General Blanketing

- Heat Treatment of Ferrous and Non-Ferrous Metals

- Inerting Flammable Liquids and Gases

- Marine

- Refineries

Standard Features:

- Activated Carbon Filter

- .01 Micron Coalescing Filter w/ drain

- Fail Safe Package (off –spec nitrogen auto-vented)

- GENERON Patent Hollow Fiber Membranes

- Inlet Pressure Gauge

- Manual Purity Control Valve

- NEMA 12 Cabinet Enclosure

- Oxygen Analyzer w/ Calibration Valve

- Outlet Pressure Gauge

- Performance Certificate

- Performance Test & Report

- PLC Control System w/ HMI Feature

- Skid w/ Lifting Lugs

- Pressure Safety Valve

Optional Features:

- Auto & Standby Mode

- Automatic Purity Control Valve

- Demister & Moister Separator

- Dew Point Analyzer

- Enhanced PLC w/ Telemetry

- Hazardous Area Classification

- Micron-Coalescing Filter

- NEMA 4X Control Cabinet Enclosure (316SS)

- Nitrogen Booster Compressor (for higher pressure applications)

- Process Heater

- Product Flow Meter

- Primary Air Compression

- Seawater-cooled Air Compressor

FEATURING

- Complete Automation & Improved Serviceability

- Completely Self-sustainable

- Enhanced Mobility & Rapid Deployment

- Environmentally Friendly – All system blow-downs captured for proper disposal

- High/Low Pressure Nitrogen Delivery Options

- No need for hauling liquid nitrogen/nitrogen tube trailers

- Rapid Set-up with Nitrogen on-line within 1 hour

- Single Platform Equipment Installation

- Wide Operational Temperature Range

Our complete systems are all packaged at our certified fabrication shop (Houston ISO 9000) to meet our clients’ exact requirements and specifications. If you’re looking to handle your short-term needs, The GENERON Group has an extensive fleet of nitrogen mobile generators available for rent through Global Nitrogen & Oilfield Services, our 100% owned subsidiary.