4000 Membrane Cabinet Series

4000 Membrane Cabinet Series

Our 4000 Series Cabinet is produced by GENERON Group, a manufacturer that has been a world leader in the industry for over 50 years. Texas Compression Services offers Nitrogen Generators varying from sizable containerized systems to cabinet design. Our systems require less power to run and lower maintenance.

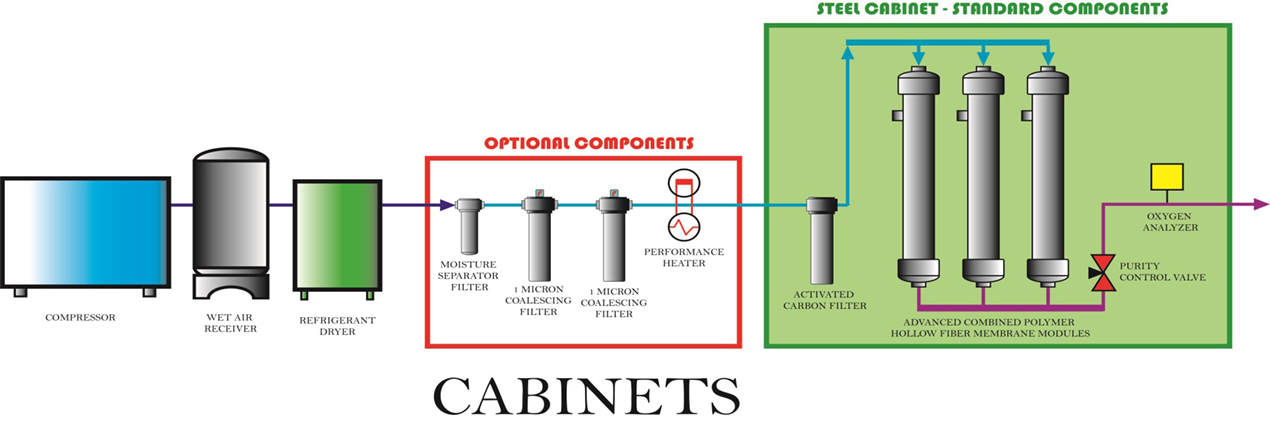

The 4000 Series Cabinet was designed using the highly engineered system, Hollow Fiber Membranes, allowing for higher flow rates in a modular setting, with each module containing thousands of fibers.

At one end of the module, compressed air passes down the fiber bores, and enriched nitrogen product gas exits from the opposite end. Water vapor and Oxygen are then discarded from the feed air while it enters the opposing end.

Common Applications

- GAIM (Gas Assisted Injection Molding)

- Re-flow & Wave Soldering of PCBs

- Inerting of Flammable Liquids and Gases

- Blanketing of Chemicals and Pharmaceuticals

- Food Packaging

- Heat Treatment of Ferrous/Non-Ferrous Metals

- Laser or Plasma Cutting

- Auto Clave

- Brazing

Benefits

- Low Gas Generating costs

- On Demand Product

- Lower dBa levels (<84 dBa)

- No Hazardous Storage/Connections

- Easy Installation

- Safe Operating Pressures

- No Moving Parts

- Easily Boost to Higher pressure

- Nearly Maintenance Free

System Details:

- Combined Polymer Hollow Fiber Membranes (allows for increased modular output performance)

- Activated Carbon Filter (integrated .01 Particulate filter wrap)

- Oxygen Analyzer w/ 2 Dry Contact Output Alarms (programmable High & Low)

- 4-20mA Output Signal

- Stainless Steel Gauges & Piping

- Factory-set Purity Control Valve

- Powder-coated Steel Enclosure

Available Options:

- Product Flow Meter

- NEMA 4X (316 Stainless Steel)

- Inlet Filtration Package

- Performance Heater

- Enhanced PLC (for Advanced option control or Telemetry)

- Auto Off Specification Circuit

- Auto Standby mode

- Auto Shut Down/Startup mode

- Automatic Purity Control (for varying flows)

- Dew Point Analyzer

- Hazardous Area Classification

- HMI Touchscreen Display (shows outlet pressure, inlet pressure, O2 concentration, system run status)

| 4000 SERIES MEMBRANE CABINET | Model Size | Inlet Pressures | ® Nitrogen Purity / Flow Rate | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| PSIG | BARG | 95% | 96% | 97% | 99.5% | ||||||

| SCFH | NM3/H | SCFH | NM3/H | SCFH | NM3/H | SCFH | NM3/H | ||||

| 210-G1 | 100 to 175 | 6.9 to 12 | 49-100 | 1.29-2.63 | 41-85 | 1.08-2.33 | 34-70 | 0.89-0.97 | 16-37 | 0.42-0.97 | |

| 210-G2 | 100 to 175 | 6.9 to 12 | 98-200 | 2.58-5.26 | 82-170 | 2.16-4.47 | 68-140 | 1.79-3.68 | 32-74 | 0.84-1.95 | |

| 330-G1 | 100 to 175 | 6.9 to 12 | 254-519 | 6.68-13.64 | 214-437 | 5.63-11.49 | 176-359 | 4.63-9.44 | 81-163 | 2.13-11.49 | |

| 330-G2 | 100 to 175 | 6.9 to 12 | 508-1038 | 13.36-27.29 | 428-874 | 11.25-22.98 | 352-718 | 9.25-18.87 | 162-874 | 4.26-22.98 | |

| 4100-G1 | 100 to 175 | 6.9 to 12 | 615-1257 | 16.17-33.04 | 518-1056 | 13.62-27.76 | 427-868 | 11.23-22.82 | 196-395 | 5.15-22.13 | |

| 4100-G2 | 100 to 175 | 6.9 to 12 | 1176-2400 | 32.23-66.08 | 1036-2112 | 27.23-55.52 | 854-1736 | 22.45-45.64 | 392-1684 | 10.3-44.27 | |

| 6150-G1 | 100 to 175 | 6.9 to 12 | 1313-2682 | 34.52-70.5 | 1105-2253 | 29-59.23 | 910-1853 | 23.92-48.71 | 419-842 | 11-22.13 | |

| 6150-G2 | 100 to 175 | 6.9 to 12 | 2626-5364 | 69-141 | 2210-4506 | 58.1-118.45 | 1820-3706 | 47.84-97.42 | 838-1684 | 22-44.26 | |

| *Flow and pressure values are averages with tolerances of ±4%. Performance data based on 40°F (4.4°C) pressure dew point and 80°F (27°C) inlet at membrane. Standard conditions: 68°F(20°C) and 14.696 PSI (1 atm). DIMENSIONS: 32″ L x 20″ W x 56″ H, WEIGHT: 70 –200 lbs. |

|||||||||||