PSA Nitrogen Generators

PSA Nitrogen Generators

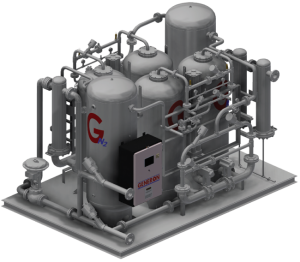

GENERON is one of the largest manufacturers of Nitrogen Pressure Swing Adsorption (PSA) Nitrogen Generators worldwide and has been designing and manufacturing PSA systems for over 50 years. We have a vast collection of 50+ standard models, so you can choose the model that’s right for you. And if you can’t find a standard model that meets your needs, we’ll build you a custom one to your exact specifications.

The GENERON Group has installed more than 2,000 systems worldwide in several markets, including Oil & Gas, Manufacturing, Petrochemical and Marine. Our manufacturer has three facilities supporting its PSA & Membrane fabrication needs. Our process and Nitrogen Membranes are all manufactured in the California Facility, system fabrication taking place in Texas and China-based facilities.

Why Choose a GENERON PSA Nitrogen Generator?

EXPERIENCE & RELIABILITY

- GENERON Group maintains one of the most impressive product portfolios in the market with 50+ standard models to choose from, flow rates to 2,030 scfm (3,200 Nm3/h) and Purities up to 99.9995%

- Assured Quality is maintained through ISO-9001 certified design & manufacturing facilities.

- The key to making an investment in Nitrogen Generation equipment is to be confident you are buying from a reliable company. GENERON Group has thousands of systems operating worldwide.

COST SAVINGS

- Continuous supply of Nitrogen

- No complicated supply contracts or escalating charges

- Cost savings of 50-300% compared to bulk liquid supply, dewar, & Nitrogen cylinders

SAFETY BENEFITS

- Eliminates the safety hazards of cryogenic liquids

- No safety/handling issues associated w/ bulky high-pressure cylinders

PSA NITROGEN GENERATION SYSTEMS:

COMPACT BANK PSA

COMPACT BANK PSA

- N₂ Capacity: 70 – 8,800 SCFH @ 100 – 145 psig

- Foot Print: 24″ – 88″ L x 20″ W x 72″ H

TWIN TOWER PSA

TWIN TOWER PSA

- N₂ Capacity: 800 – 112,000 SCFH @ 100 – 145 psig

- Foot Print: 58″ – 156″ L x 52″ – 120″ W x 58″ – 156″ H

SEQUENTIAL PSA

SEQUENTIAL PSA

- N₂ Capacity: up to 254,000 SCFH @ 100 – 145 psig

- Foot Print: 116″-240″” L x 96″ W x 108″ H

CONTAINERIZED SYSTEM

CONTAINERIZED SYSTEM

with feed compressions & pre-treatment

- N₂ Capacity: 600 – 25,000 SCFH @ 100 – 145 psig

- Foot Print: 240″ – 480″ L x 96″ W x 114″ H

What Is a PSA Nitrogen Generator?

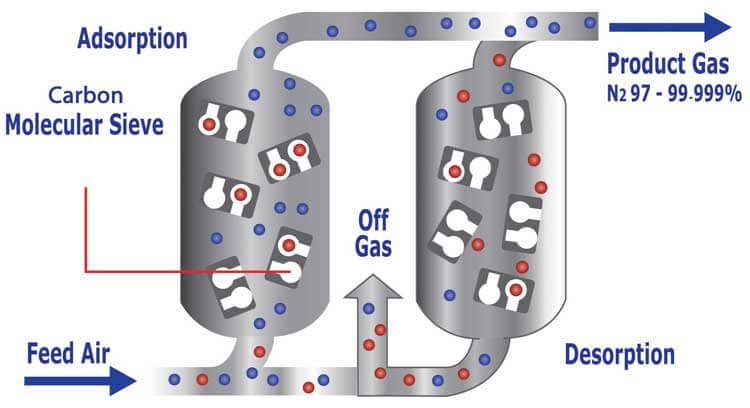

Pressure Swing Adsorption is a technology used for separating gas species from a mix of various gases under pressure, depending on the affinity for an adsorbent material and the species’ molecular characteristics. This technology differs significantly from cryogenic-distillation gas separation techniques. Specific adsorptive materials, such as activated carbon or molecular sieves, are used as a trap, adsorbing the target gas species at a high pressure. Operating at near-ambient temperatures, the process swings to low pressure, desorbing the adsorbed material.

How Do Industrial PSA Nitrogen Generators Work?

For this process, pressure swing adsorption relies on the principle that under high pressure, gas tends to be attracted to solid surfaces. Higher pressures result in more gas being adsorbed. When pressure is reduced, adsorbed gas is then released (desorbed). Pressure Swing Adsorption processes are often used to separate gases from mixtures because different gases are attracted to different solid surfaces more/less strongly. For example, if air (gas mixture) passes under pressure through a particular vessel containing an adsorbent bed of CMS (which attracts O2 more strongly than it does N2), some or all of the oxygen will remain in the bed, and gas exiting the vessel will then be enriched in N2. When the bed reaches its capacity’s end to adsorb oxygen, it can regenerate by reducing pressure, consequently releasing adsorbed oxygen. It can then begin the cycle again and produce more high purity N2 gas.

Using two (2) adsorbent vessels allows for near-continuous production of target gas. This technique also permits pressure equalization, which is where gas leaving a depressurized vessel is used to partially pressurize a second vessel. This common industrial practice leads to significant energy savings.

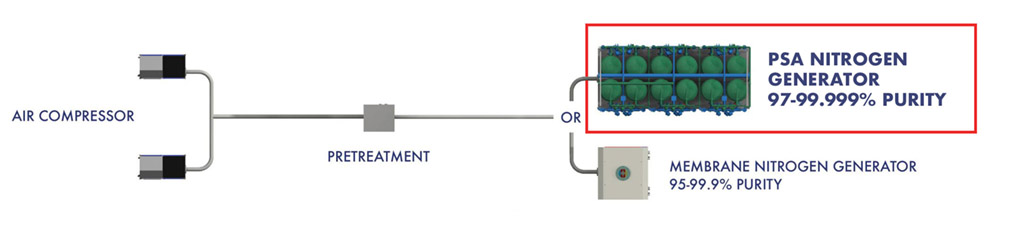

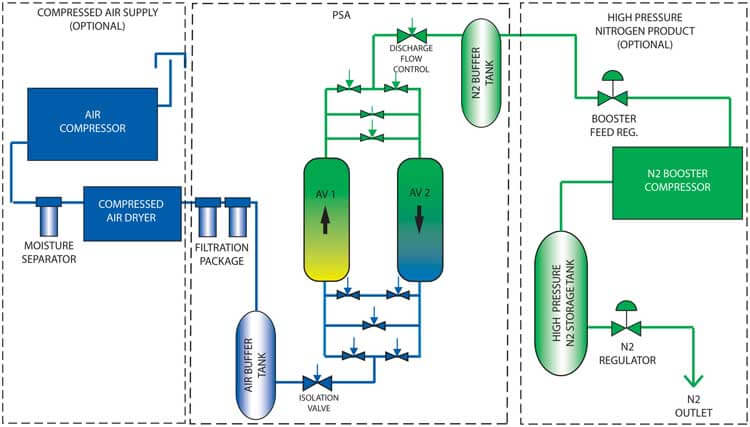

Typical System Configuration (PFD)

System Specification

- The GENERON Group offers completely turn-key system designs, including all components, elements, and design drawings. Our engineering teams will work directly with you to design and install systems to your exact specifications. Our full-service team is ready to answer any questions you may have 24/7.

Technology

How Does a Pressure Swing Adsorption System Work?

Nitrogen PSA Generator Systems send air over a bed of adsorbent material, which bonds with O2 and leaves a rich stream of nitrogen gas to exit.

Adsorption separation is achieved by the following steps:

FEED AIR COMPRESSION & CONDITIONING

The ambient inlet air is compressed, dried by an air dryer, filtered, all before entering the process vessels.

PRESSURIZATION & ADSORPTION

The pre-treated filtered air is then directed into a CMS-filled vessel, where oxygen is adsorbed preferentially into the CMS pores. This permits concentrated nitrogen, with adjustable purity as low as 50 ppm O2, to stay in the gas stream until it flows out of the vessel. The separation process interrupts the inlet flow (before the full adsorption capacity of the CMS is reached) and finally switches over to the other adsorber vessel.

DESORPTION

The O2-Saturated CMS is then regenerated by means of pressure reduction, below the previous adsorption step. It achieves this by using a pressure release system where exhaust/waste gas stream is carefully vented from the vessel, typically through a diffuser/silencer, then back into the safe surrounding atmosphere. Regenerated CMS is now refreshed and can be used again for generating nitrogen.

ALTERNATING VESSELS/SWING

Desorption and Adsorption should take place at equal time intervals, alternately. This way, the constant generation of nitrogen is be achieved by using two (2) adsorbers. As one is adsorbing, the second is in regeneration mode. Constant switching back and forth results in a controlled and continuous flow of nitrogen.

NITROGEN RECEIVER

Continuous nitrogen product flow & purity is maintained by a connected product buffer vessel which stores the N2 output. This is designed for a pressure up to 150 psig (10 bar) and Nitrogen purity up to 99.9995%.

NITROGEN PRODUCT

The resulting product is a constant stream of high purity, on-site produced Nitrogen, and costs significantly below the standard price of liquid/bottled gases.